Particularly promising engineering for the uses of new generation batteries pure lithium metalIt is a material with excellent energy density that could make electric vehicles move longer distances with each charge. A research group in the United States has taken an important step forward with this technology by proposing a design for Lithium-metal battery lasts for a record number of charge cycles.

The idea behind these types of batteries is to replace the graphite used in the anode component with pure lithium metal, which can hold up to 10 times more energy.

Described by some researchers as the dream material, lithium metal is seen as the key to helping overcome a major bottleneck in energy storage, but scientists have struggled with longevity issues and with versions so developed that they quickly fail during use.

One reason for such failures is the complex interactions that occur around the anode, which affect a thin film above it known as the solid electrolyte interphase (SEI). This film controls the molecules entering the anode of the electrolyte solution, through which electrons travel back and forth to and from the battery’s other electrode, known as the cathode.

In this way, the role of this gatekeeper puts the SEI in charge of preventing unwanted chemical reactions while the battery is being recharged, and it is this mechanism that scientists at the US Department of Energy’s Pacific Northwest National Laboratory (PNNL) are targeting in a new studio. It is common knowledge that charging the amount of lithium in the anode was one way to address this problem, but the team succeeded with another approach.

“Many people thought that thicker lithium would allow the battery to work longer,” says Ji Xiao, author of the corresponding article. “But this is not always true. There is an optimized thickness for each lithium-metal battery depending on cell power and design.

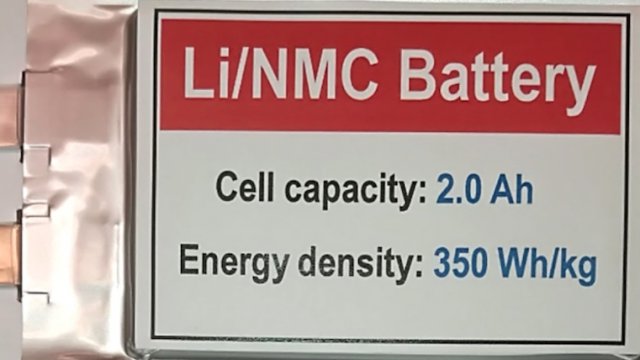

The scientists used very thin strips of lithium as the basis for their anode, each only 20 microns wide – much thinner than a human hair. This anode was placed in a pocket battery with a power density of 350 W/kg. The best lithium-ion batteries in use today have densities of 250 to 300 W/kg, so while 350 W/kg is unheard of in research circles, it’s a marked improvement over currently available technologies.

during the tests, The team found that the battery maintained 76% of its capacity after 600 record cycles. The same researchers demonstrated an experimental lithium battery that could run for 50 cycles four years ago, and then one capable of 200 cycles two years ago. This current record-breaking version is another major step forward, and according to the team, it lasts much longer than any other version being developed in similar research projects.

The team attributes the project’s success to the way thin tapes facilitate improved SEI and thus better electrolyte-anode interactions, compared to thicker tapes that stifle important electrochemical reactions. After solving a major problem with lithium-metal batteries, the authors hope to further improve the technology through a multi-institutional consortium known as Battery500, which is working towards a power density of 500 W/kg.

“The Battery500 consortium has made significant progress in increasing energy density and extending cycle life,” says Stanley Whittingham, 2019 Nobel Prize winner in Chemistry and co-author of the research paper. But there is much more to be done. Especially, There are safety concerns regarding lithium-metal batteries that need to be addressed. It’s something the Battery500 team is working hard to fix.”

The research was published in the journal Nature Energy.

“Web fanatic. Travel scholar. Certified music evangelist. Coffee expert. Unapologetic internet guru. Beer nerd.”