Artificial intelligence (AI) has been a very current topic in the media for several years. However, it has not yet been discovered on the factory floor. There are different reasons for this: On the other hand, there is a lack of data because machines are used to carry out their production steps. It is designed, but not to provide data. However, these are indispensable for a digital twin. The digital twin is the virtual image of a real event. On the other hand, this includes data that provides real events (such as machines, processes, and people). On the other hand, algorithms are needed to analyze this data and understand the behavior. The “business” that is reflected in the data is put into the logic. Once this logic is recognized, reliable statements about future actions and developments can be made.

Why is AI getting easier and easier

This will be easier in the future, because the leading machine makers have been offering “internet-enabled” machines for several years, that is, systems that save the data generated and thus make it available for analysis. On the other hand, this is also due to the great complexity of variables, for example in the automotive sector: each time a car is ordered, the customer individually configures his dream car with a batch size of 1. In almost all industries, there is a trend that must master this production Increasingly a large number of product variants. This presents a challenge for AI algorithms in production control, as they have to frequently adapt to changing products and production conditions. So, if reality changes over and over again, the “reflection” of reality, the digital twin, and AI analytics based on it, must also identify those changes. A complex problem — but there are solutions: self-learning AI algorithms that understand changes in production and can derive what those changes mean for AI analytics. These AI algorithms independently adapt mathematical AI models in order to provide accurate predictions or forward-looking recommendations for continuous action.

Here are two examples of how AI has been able to produce reliable data because AI algorithms have adapted – despite complex and changing production processes.

Auto supplier example: predicting quality using AI and taking countermeasures

In quality inspection, it would be ideal to test the quality at the end of each critical production step. However, this would be a waste of time. Therefore, self-learning AI processes learn during the production step whether the quality indicators have been achieved or not. If not, you can either take countermeasures to avoid rejection. Or – if this is no longer possible – the production step is eliminated to save production time and reduce machine wear and operating costs.

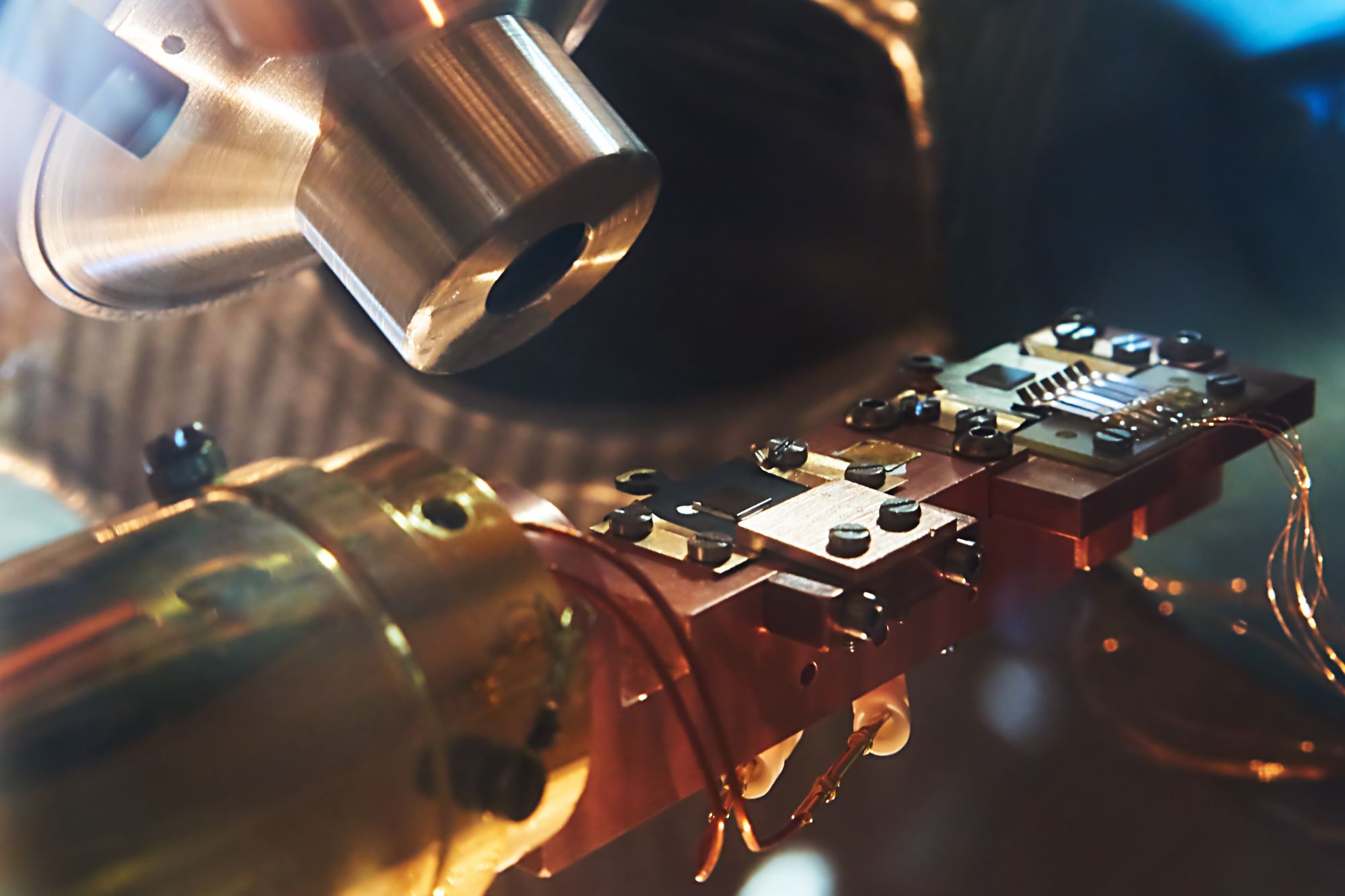

This was also the desire of an international auto supplier that manufactures many variants of its products. Production steps are highly automated; This also applies to the processing of injection nozzles with spindles. There are about 20 cutting machines for this production step. Even though they all do the same thing, use the same tools, have the same setup, use the same materials from the same supplier, etc., sometimes it happens that one machine and other times offers poor quality.

“Certified gamer. Problem solver. Internet enthusiast. Twitter scholar. Infuriatingly humble alcohol geek. Tv guru.”